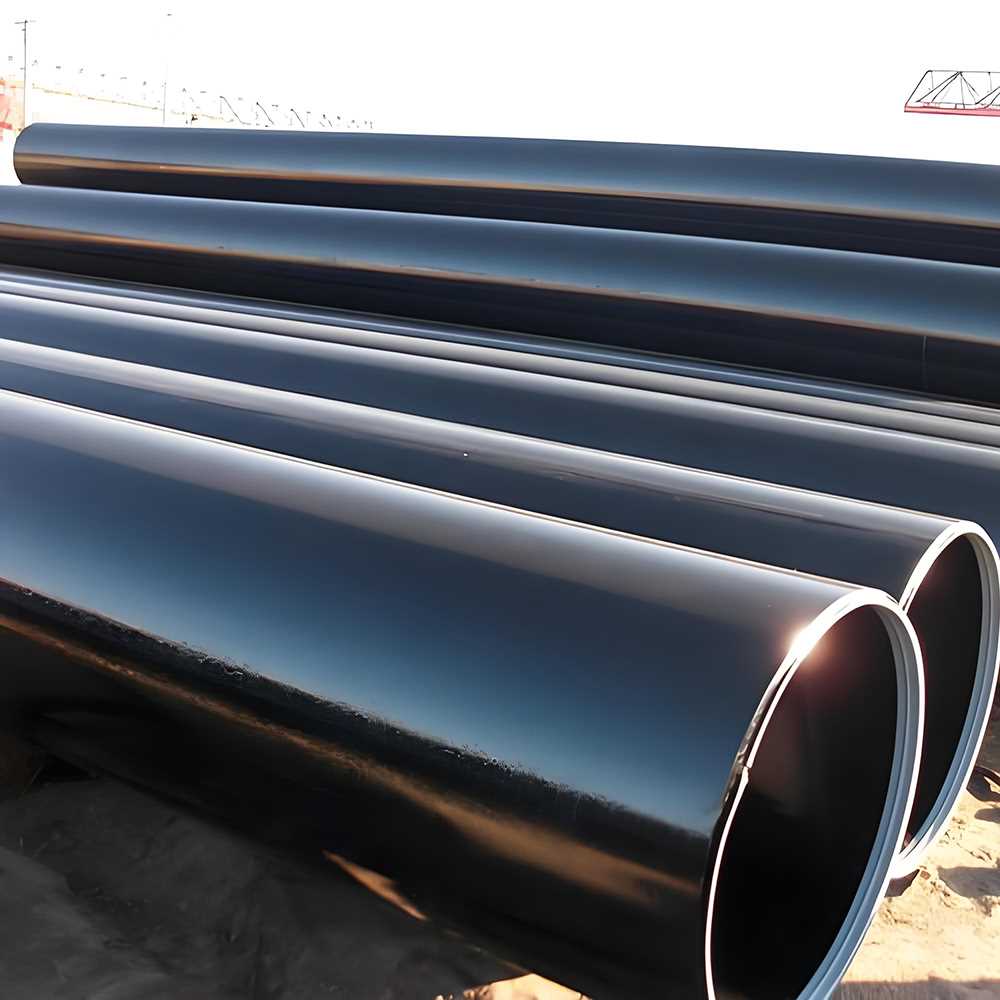

I. Introduction of ERW Black Steel Pipe

ERW black steel pipe, also known as ERW LSAW pipe, is mainly divided into two forms: ERW AC welded steel pipe and ERW DC welded steel pipe.

ERW LSAW pipe is also divided into low frequency welding, medium frequency welding, super medium frequency welding and high frequency welding according to the different frequencies.

II. ERW Black Steel Pipe Manufacturing Process

(1) Raw Material Preparation: Select steel strips and clean their surfaces. Some products can be further processed into welding galvanized steel pipes to enhance their corrosion resistance.

(2) Uncoiling and Forming: After uncoiling, the steel strips are gradually bent into a circular tube shape using a forming machine.

(3) Welding: High-frequency current is used to weld the edges of the blank into a weld seam, forming the basic structure of carbon steel welded pipes.

(4) Weld Inspection: Non-destructive testing techniques are used to inspect weld quality.

(5) Cooling: The welded steel pipes are cooled using water cooling or air cooling.

(6) Straightening: The steel pipes are straightened using a straightening machine.

(7) Cutting: The steel pipes are cut to the specified length according to requirements.

(8) Inspection and Packaging: After comprehensive inspection, the products are packaged and stored.

III. Common international standards for ERW black steel pipes

| Country/Region | Standard Name | Standard Number |

|---|---|---|

| China | GB/T 3091-2015 Welded steel pipes for fluid transport | GB/T 3091-2015 |

| United States | ASTM A53/A53M Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless | ASTM A53/A53M |

| Germany | DIN 2391-2:2007 Seamless and welded circular hollow sections - Part 2: Hot-finished circular hollow sections | DIN 2391-2:2007 |

| United Kingdom | BS 1387:1985 Specification for steel tubes for general purposes | BS 1387:1985 |

| Japan | JIS G3444:2007 Welded Steel Tubes for general structural purposes | JIS G3444:2007 |

| Russia | GOST 10704-91 Welded steel pipes | GOST 10704-91 |

| France | NF A49-005 Welded steel pipes | NF A49-005 |

| Italy | UNI 3606:1999 Welded steel pipes | UNI 3606:1999 |

| India | IS 1239 (Part 1):2004 Welded steel tubes | IS 1239 Part 1:2004 |

IV. Key Advantages of ERW Black Steel Tubes

(1) High Strength and Reliability

ERW black steel pipes utilize resistance welding technology, resulting in high weld seam strength and ensuring reliability under high-pressure conditions. Their mechanical properties are uniform, meeting the demands of various industrial applications.

(2) High Dimensional Accuracy

Employing advanced control technology, ERW black steel pipes achieve precise control over dimensions and roundness, making them ideal for projects requiring high-precision tubing.

(3) High Production Efficiency

The production process of ERW black steel pipes is highly automated, with fast forming and welding speeds, effectively improving production efficiency, shortening delivery times, and reducing production costs.

(4) Cost-effectiveness

Compared to other types of pipes, ERW black steel pipes have high raw material utilization rates and low production costs, making them particularly suitable for large-scale procurement and long-term use.

(5) Environmental Friendliness and Sustainability

The production process of ERW black steel pipes has low energy consumption, and the pipes can be recycled and reused after production, helping to reduce environmental impact.

(6) Wide Range of Applications

ERW black steel pipes are available in various specifications and are widely used in industries such as construction, oil and gas, and machinery manufacturing. Additionally, carbon steel pipes and alloy steel pipes are preferred materials for some industries with special requirements.

(7) Excellent Surface Quality

ERW black steel pipes have a smooth surface with good coating adhesion, making them suitable for environments requiring high surface quality, such as chemical and oil pipeline construction.

(8) Consistent Quality

Strict quality control ensures the consistency of ERW black steel pipe products, meeting the needs of different markets and projects. In comparison, the quality of double-sided submerged arc welded pipes is also subject to the same strict monitoring, but ERW black steel pipes have a clear advantage in production efficiency.

V. Applications of ERW Black Steel Pipes

(1) Oil and Gas Industry

Commonly used for the transportation of oil and natural gas, ensuring safe transportation under high-pressure conditions.

(2) Construction Industry

As a key material for building frameworks and support structures, it provides robust structural support and is widely applied in various construction projects.

(3) Mechanical Manufacturing

Used as components and equipment frameworks in mechanical manufacturing, meeting diverse industrial requirements and providing reliable mechanical performance.

(4) Chemical Industry

Due to its excellent corrosion resistance, it is widely used for the transportation of chemicals and corrosive media, suitable for various chemical engineering projects.

(5) Municipal Engineering

In municipal construction, it is used for water supply, drainage, and gas pipelines, ensuring the safety and stable operation of urban infrastructure.

(6) Automotive Manufacturing

Used in automotive components and exhaust systems, it provides strength and durability, ensuring the long-term use of automotive parts.

(7) Marine Engineering

Widely used in offshore platforms and subsea pipelines, capable of withstanding the challenges of extreme marine environments.

(8) Other Fields

In addition to the above fields, it is also applied in agricultural irrigation, power transmission, and other industries.

As a welded steel tube manufacturers, we are committed to producing high-quality ERW black steel pipes to meet the needs of various engineering projects and industries.