Stainless steel welded pipe, referred to as welded pipe, commonly used steel or steel strip through the unit and mold crimping forming after welding made of steel pipe. Welded steel pipe production process is simple, high production efficiency, more varieties and specifications, less investment in equipment, but the general strength is lower than seamless steel pipe.

I. The characteristics of stainless steel welded pipe

i. Wall thickness is significantly associated with the economy

Small diameter stainless steel welded pipe adopts continuous online production mode. When the wall thickness increases, the investment cost of the unit and welding equipment rises sharply, resulting in a reduction in economy and practicality; and when the wall thickness is too thin, the ratio of production inputs to outputs and benefits will also decline.

ii. Process determines core advantages

Its production process gives the product a number of advantages:

High precision: through automated molding and welding technology, the pipe size is precisely controlled.

Uniform wall thickness: rolled from high-quality cold-rolled steel plate, with very small thickness tolerance and better uniformity than traditional seamless pipes.

Excellent surface brightness: The surface grade of the steel plate directly affects the finished pipe’s internal and external wall finish, which usually reaches the standard of industrial clean surface grade.

iii. Flexible Sizing Capability

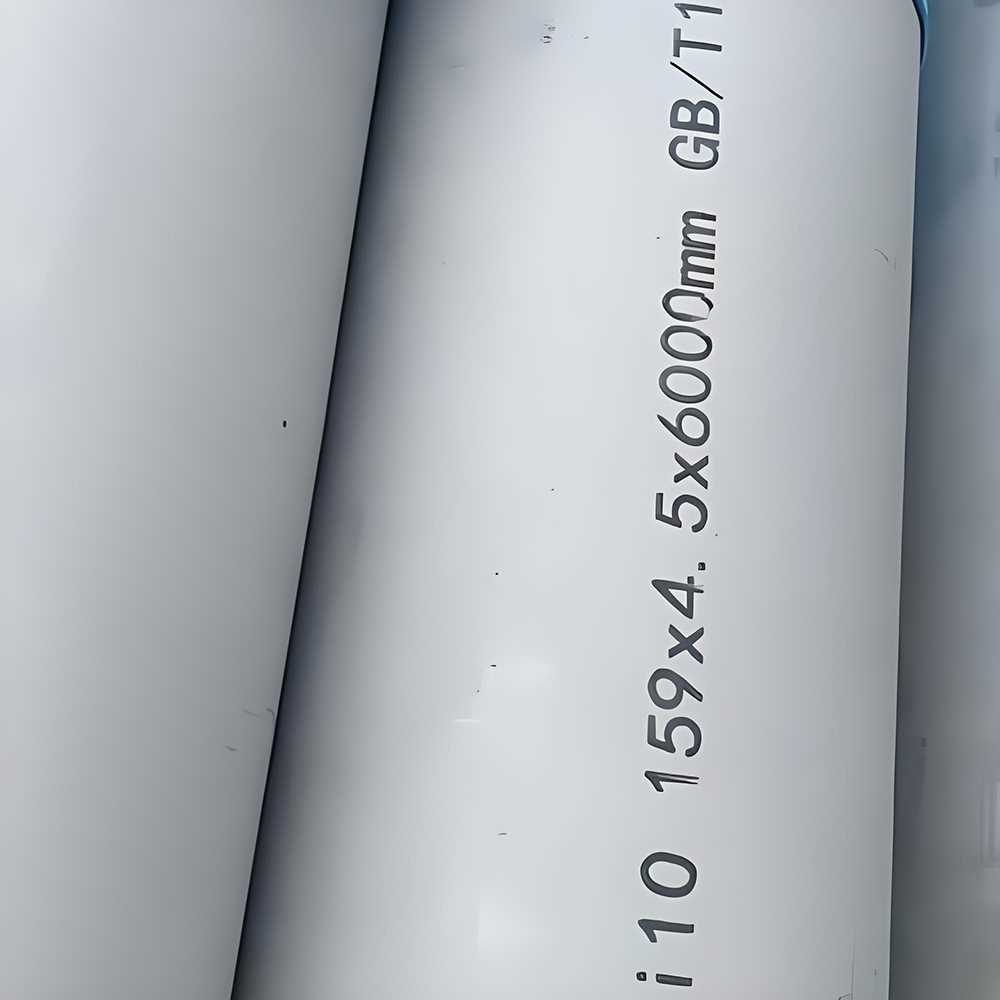

The length of the pipe can be customized according to the demand, avoiding the high cost of traditional seamless pipe sizing process, especially suitable for engineering scenarios that require accurate sizing.

iv. Advantages of application scenarios

With high precision, low cost and aesthetics, stainless steel welded pipes are used in low and medium pressure fluid transportation (e.g. chemical and food industry piping), decorative engineering (e.g. building guardrail) and other scenarios, which are both functional and economical, and are gradually replacing some of the seamless pipe applications.

v. Stable material properties

Adopting on-line bright solution treatment technology to eliminate residual stresses, the intergranular structure between weld and base material is consistent, ensuring uniform mechanical properties. Meanwhile, quality control means such as eddy current testing are adopted to guarantee product reliability.

II. Classification of stainless steel welded pipe

i. Classification according to the form of welded seam

(1) straight seam welded pipe

Simple production process, high production efficiency, low cost.

The weld seam is parallel to the longitudinal direction of the steel pipe, suitable for small caliber (usually ≤ 406mm) scenes, such as building decoration, low pressure fluid transportation.

(2) Spiral welded pipe

The strength is higher than LSAW pipe, and can be used to produce large caliber pipe (usually ≥219mm) with narrower steel strip.

The weld seam is spiral, the length is increased by 30%-100%, the production speed is lower, but it is suitable for oil and natural gas long-distance transportation pipeline.

ii. Classification by use

(1) general welded pipe

Used for low-pressure fluid transportation (such as water, gas, air), the material is mostly Q195-Q235 carbon steel.

(2) Galvanized welded pipe

Surface galvanized to enhance corrosion resistance, divided into hot-dip galvanized (high corrosion resistance) and electro-galvanized (low-cost), commonly used in construction, agriculture and so on.

(3) Heat exchanger tubes/condenser tubes

Applied to heat exchange equipment, the material is mainly stainless steel (e.g. 304, 316L), requiring high precision and corrosion resistance.

(4)Oxygen blowing welded pipe

Used for steel blowing oxygen, small diameter (3/8-2 inches), made of 08, 10, 15 steel, partially aluminized.

(5) Wire Sleeves

Thin-walled tubes for protecting circuits, need to meet the requirements of the cold bending test, mostly made of ordinary carbon steel.

(6)Metric welded pipe

Produced according to the specifications of seamless pipe, used for mechanical structural parts (such as drive shafts) or decorative areas (such as furniture, lamps and lanterns).

(7)Roller tube/deep well pump tube

Roller tubes are used for conveyor rollers and need to pass water pressure and flattening tests; deep well pump tubes are used for pumping equipment, emphasizing sealing and strength.

(8)Automobile

Tubes/Transformer Tubes

Tubes for automobiles need to be lightweight and high-precision; transformer tubes are used for heat dissipation systems and are made of low carbon steel.

(9)Electro-welded thin-walled tube/shaped tube

Thin-walled tubes are used in lightweighting scenarios (e.g. furniture, lamps); profiled tubes (square, rectangular, etc.) are used for special structural components with both bending and torsion resistance.

(10) Spiral welded pipes (listed separately by application)

Dedicated to high-pressure or high-flow scenarios such as oil and gas transportation, piling works, etc. The materials cover carbon steel and stainless steel.

III. National standards for stainless steel welded pipes

i. China National Standard (GB)

(1)Stainless steel welded steel pipe for fluid transportation

Standard No.: GB/T 12771-2019 (replace GB/T 12771-2008)

Scope of application: fluid transportation (such as water, gas, corrosive media).

Technical requirements:

Material: including 022Cr19Ni10 (304L), 06Cr17Ni12Mo2 (316) and other 12 stainless steel grades, deleted martensitic steel.

Process: automatic arc welding or laser welding, the weld needs to pass the ray detection, hydraulic/gas tightness test.

Testing: new grain size requirements (4-7 levels), weld transverse bending test, modify the flattening test and weld residual height requirements.

(2) Stainless steel welded steel pipe for mechanical structures

Standard No.: GB/T 12770-2012 (replace GB/T 12770-2002)

Scope of application: mechanical components, automobiles, furniture and other structural components.

Technical requirements:

Material: 0Cr13, 1Cr17, 00Cr19Ni11, etc., focusing on strength and processing performance.

Testing: flattening test, flaring test, weld transverse bending test is required for steel pipe with OD ≥ 219mm.

(3) Other related standards

GB/T 20832-2008: Duplex stainless steel welded steel pipe (austenitic – ferritic duplex steel), austenite is required to account for 40% -60%, weld ray detection and flattening test.

GB/T 14976-2012: stainless steel seamless steel pipe for fluid transportation, as an alternative standard for welded pipe, limiting phosphorus content (P≤0.035%).

ii. International Standards

(1) American Standard (ASTM)

ASTM A554: Stainless steel welded steel pipe for mechanical structure, non-equivalent adopted from China GB/T 12770.

Material: 304, 316, etc., emphasizing corrosion resistance and strength of welded joints.

ASTM A240: Stainless steel plate and strip standard for welded pipe raw materials, specifying the chemical composition and mechanical properties.

(2) European standards (EN/DIN)

DIN EN 10088-1: General stainless steel material standard, covering welded pipe material selection, corrosion resistance and processing performance.

EN 10217-7: Stainless steel welded pipes for pressure purposes, requiring hydraulic testing and ultrasonic testing, for industrial piping.

(3) Japanese Standard (JIS)

JIS G4303: general standard for stainless steel materials, the chemical composition of the welded pipe (such as SUS304, SUS316) and mechanical properties.

JIS G3446: stainless steel welded steel pipe for mechanical structure, similar to China GB/T 12770, emphasizing dimensional accuracy and surface quality.

(4) International General Standard (ISO)

ISO 1127: Stainless steel pipe dimensional standards, defining the outer diameter, wall thickness tolerance, and GB/T 12771 part of the same indicators.

ISO 2037: stainless steel welded pipe for food industry, requiring high cleanliness surface treatment (Ra ≤ 0.8μm).

iii. Core Differences Comparison

| Item | Chinese Standard (GB) | American Standard (ASTM) | European Standard (EN) |

|---|---|---|---|

| Material Range | Focus on austenitic and duplex stainless steel | Covers a wide range of 300/400 series | Emphasizes environmentally friendly low-nickel steel grades |

| Inspection Requirements | Mandatory grain size testing and weld bend testing | Focus on chemical composition and impact testing | Requires environmentally friendly processes and carbon footprint assessment |

| Application Fields | Mainly chemical and construction | Mainly petroleum and nuclear power | Mainly food and medical |

IV. Industry application and standard selection

Oil & Gas: API 5LC (Hydrogen Sulfide Corrosion Resistant Welded Pipe) or GB/T 12771 high pressure version is preferred.

Food and medical: ISO 2037 or GB/T 12771 high surface grade requirements (e.g. internal and external mirror polishing) need to be met.

Architectural decoration: GB/T 12770 or ASTM A554 is applicable, focusing on aesthetics and sizing accuracy.